Introduction

In the ever-evolving box of electronics manufacturing, twine bonding has emerged as a an important technique for beginning electrical connections between semiconductor gadgets. It serves as a bridge among exclusive formula, making sure that indications are transmitted efficaciously and reliably. However, as with all production method, there's a sensitive balance among money and fine that would have to be maintained to acquire highest quality effects. This article delves deep into the intricacies of balancing charge and first-class within the wire bonding manner, exploring more than a few tactics, applied sciences, and packages within this essential box.

Understanding the Wire Bonding Process

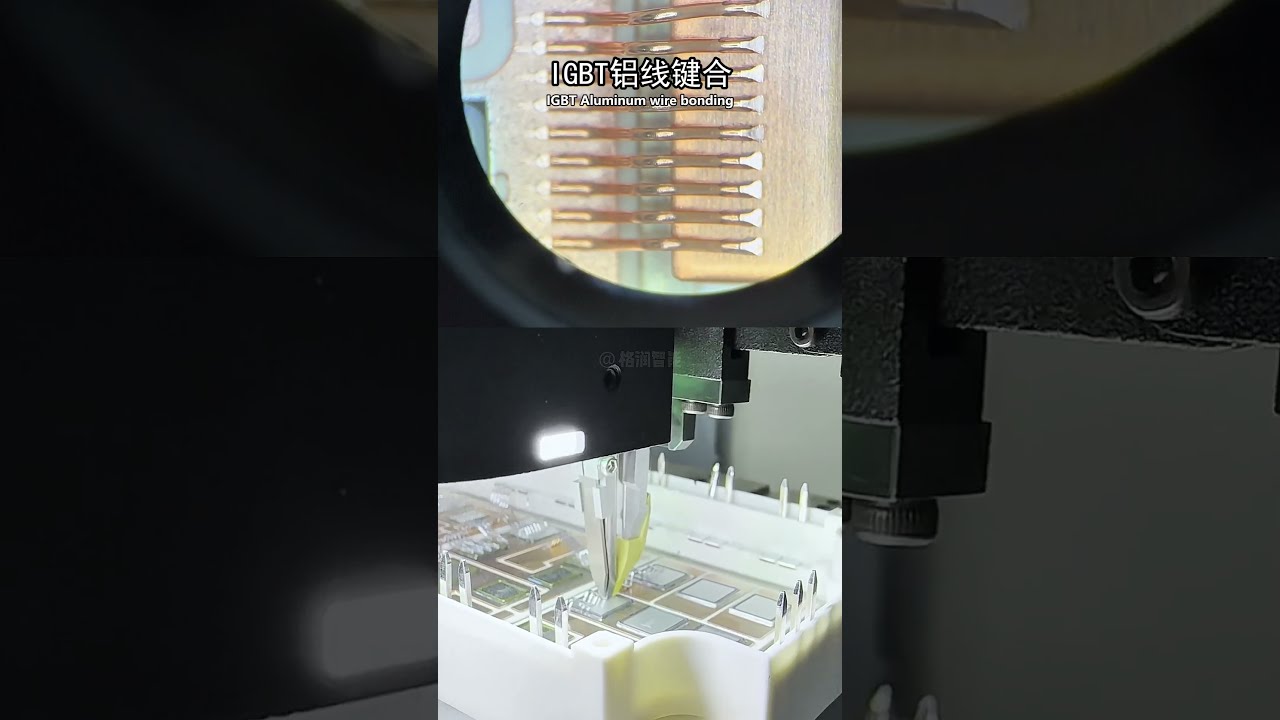

What is Wire Bonding?

Wire bonding is a way used to connect microelectronic factors because of thin wires. Commonly employed in semiconductor packaging, it creates electric connections among chips and substrates or amongst the several chips.

How Does Wire Bonding Work?

The twine bonding procedure will probably be finished through various processes, along with ball bonding and wedge bonding. Essentially, superb wires—quite often product of gold, aluminum, copper, or silver—are hooked up to bonding pads on a semiconductor equipment driving warm and drive.

Types of Wire Bonding

There are more often than not 3 sorts of cord bonding tools:

- Ball Bonding: Involves growing a small ball on the stop of the twine before it makes contact with the bond pad. Wedge Bonding: Utilizes a wedge-fashioned software to press the cord onto the pad with out forming a ball. Ribbon Bonding: Employs flat ribbon wires rather then around ones for exclusive programs.

Each technique has its benefits and drawbacks involving check and reliability.

Wire Bonding Technology: An Overview

The Evolution of Wire Bonding Equipment

From manual machines to utterly automated platforms, twine bonding package has viewed gigantic developments over time. Modern machines are prepared with improved options including programmable settings for superb-tuning parameters like temperature and drive.

Key Components of Wire Bonding Machines

A normal cord bonding machine includes:

- Bond Head: Where the proper bonding takes situation. Capillary Tool: Guides the cord at some point of the bonding manner. Ultrasonic Generator: Provides electricity for ultrasonic bonding concepts.

Understanding these additives helps manufacturers decide ideal appliance that aligns with their can charge-satisfactory steadiness pursuits.

Balancing Cost and Quality in Wire Bonding

The Importance of Cost vs. Quality

When it involves twine bonding methods, producers sometimes face a trouble between minimizing expenditures and conserving prime first-class requirements. A concentrate on settlement discount can end in subpar bonds that would fail through the years or less than tension.

Factors Influencing Cost in Wire Bonding

Some key causes influencing rates embody:

Wire Material: Gold is extra luxurious than aluminum or copper however can provide choicest conductivity. Machine Efficiency: Older machines might require extra repairs and bring scale back yield premiums. Labor Costs: Automating strategies can cut back labor fees but calls for preliminary investment.Ensuring High Quality in Wire Bonds

Quality keep an eye on is paramount in guaranteeing reputable electric connections. Techniques similar to visual inspection, X-ray evaluation, and pull checking out lend a hand name skills problems prior to they improve into disasters.

Wire Bonding Applications Across Industries

The Role of Wire Bonding in Semiconductors

In semiconductors, respectable connections are relevant for capability. Wire bonding guarantees that integrated circuits can be in contact competently inside of electronic instruments.

Wire Bonding Applications in Automotive Electronics

Automotive packages call for high reliability by means of varying environmental prerequisites. Here, tough wire bonds contribute enormously to safe practices-primary methods like airbag deployment mechanisms.

Medical Devices and Wire Bonding Technologies

In clinical contraptions in which reliability is non-negotiable, top quality twine bonds warrantly functionality underneath rigorous stipulations.

Wire Bond Failure Analysis

Common Causes of Wire Bond Failures

Understanding why bonds fail can assistance producers take preventive measures. Common failure modes come with:

- Poor floor practise Improper fabric range Insufficient bond energy

Analyzing Failures: Best Practices

Conduct thorough failure analyses with the aid of applying non-negative testing equipment like X-ray inspection or pull assessments to accumulate insights into bond integrity concerns.

Assessing Reliability in Wire Bonds

Measuring Reliability Through Testing Standards

Reliability assessments commonly make use of standardized testing protocols including JEDEC guidelines which outline perfect efficiency stages beneath distinctive situations.

Long-Term Reliability Considerations

Factors which includes thermal cycling effortlessly or moisture sensitivity can influence lengthy-time period reliability; accordingly right encapsulation innovations have to be seen throughout layout phases.

Cost-Saving Strategies Without Compromising Quality

Optimizing Material Selection

Choosing substances correctly based mostly on software standards can bring about widespread reductions whereas declaring imperative au ball wire bonding efficiency phases.

| Material | Advantages | Disadvantages | |----------|------------|---------------| | Gold | Excellent conductivity | High value | | Aluminum | Cost-fine | Less conductive | | Copper | Good conductivity & low settlement | Susceptible to oxidation |

Lean Manufacturing Principles

Adopting lean ideas can streamline operations major to diminished waste even though bettering product high-quality as a result of useful use of instruments.

Innovations in Wire Bonding Technologies

Industry four.0 Impact on Wire Bonding

The integration of good technology enables for true-time monitoring of bond satisfactory foremost to instantaneous corrective moves whilst deviations occur from set parameters.

Emerging Trends in Wireless Communication Devices

The upward thrust of 5G generation necessitates advanced twine bonding suggestions able to helping excessive-frequency functions devoid of compromising signal integrity or growing quotes excessively.

Training Programs for Effective Implementation

Educational Resources Available

Invest in workout components like webinars or palms-on workshops targeted on present day cord bonding ways designed for engineers and technicians alike taken with honing their abilties similarly.

Recommended Training Programs:

University-led courses Online tutorials (YouTube motion pictures) PDF publications achieveable via trade associationsFAQs approximately Balancing Cost and Quality in the Wire Bonding Process

What is wire bonding?- It's a means used mostly for connecting electronic materials using skinny wires.

- Common components incorporate gold, aluminum, copper, and silver caused by their conductive residences.

- Implement regular inspections applying X-ray analysis or pull checks to investigate bond integrity.

- Poor surface education, flawed material determination, inadequate bond strength

- Automation at first incurs upper charges but leads to long-time period savings by means of lowering exertions demands and getting better yield charges.

- Yes; ball binding uses a small ball at the quit whereas wedge binding employs flat ideas with out forming balls for genuine functions.

Conclusion

Balancing expense and great in the cord bonding method is obviously difficult but achievable with strategic planning and careful execution throughout diverse aspects—which includes drapery selection, kit alternative, and adherence to stringent best keep watch over measures. As expertise advances preserve shaping this area—from rising conversation standards like 5G at some stage in imaginitive machinery—the need will stay for producers who prioritize the two potency at the same time as delivering extraordinarily safe electronic connections throughout industries ranging from automotive electronics as a result of scientific devices up except aerospace programs subsequently paving way toward future improvements too!