Introduction

In the difficult world of electronics, wire bonding stands as a pivotal methodology for starting electrical connections among semiconductor gadgets. As technological know-how advances, ensuring the reliability and efficiency of cord bonding tactics has develop into paramount. This article delves into the comprehensive diagnosis of cord bonding mess ups, imparting insights into strategies, methods, and excellent practices that experts can rent to look after in opposition to energy pitfalls within the twine bonding process.

Wire bonding is absolutely not just a ordinary project; it’s an amalgamation of precision engineering and developed technologies. Whether you’re dealing with gold twine bonding, aluminum wire bonding, or exploring the nuances of ribbon and wedge bonding suggestions, knowing the intricacies in contact in engaging in wonderful twine bonding failure research is simple.

What is Wire Bonding?

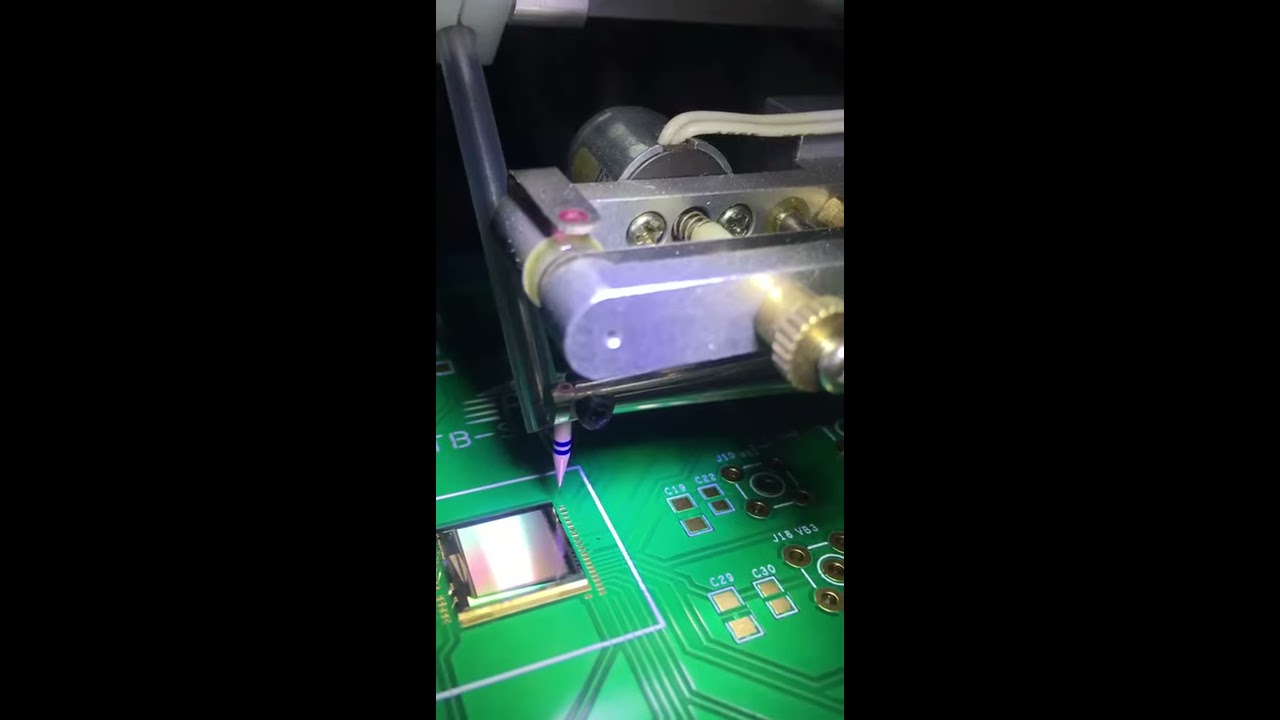

Wire bonding is a strategy used to connect microelectronic areas using thin wires. This strategy serves as the backbone for legitimate electrical connections in various purposes starting from person electronics to car systems. In essence, it consists of via a cord bonding machine that employs warm and drive to create metallic bonds between wires and pads on semiconductor chips.

The Wire Bonding Process: An Overview

The wire bonding process encompasses a few serious steps:

Preparation: The surfaces will have to be refreshing and unfastened from infection for surest bond nice. Placement: The twine is situated properly the use of specialised machine. Bonder Activation: Heat and ultrasonic potential are implemented to create a bond. Loop Formation: A loop is fashioned to accommodate thermal expansion. Finalization: The bond is inspected for integrity.Understanding these steps allows engineers pick out in which disasters would possibly appear at some stage in construction.

Conducting Effective Wire Bonding Failure Analysis

When it involves making sure reliability in cord bonding, studying mess ups becomes fundamental. Failures can rise up by means of various factors which includes kit malfunctions, textile inconsistencies, or environmental stipulations affecting the bonds’ integrity.

Types of Wire Bonding Techniques

- Ball Bonding Wedge Bonding Ribbon Bonding

Each technique has its own set of blessings and downsides relying on the program—whether or not it really is for prime-frequency applications or powerful automobile electronics.

Key Factors Influencing Wire Bonding Reliability

Material Selection: Gold vs aluminum can tremendously have an impact on functionality. Bonding Parameters: Temperature, pressure, and time will have to be optimized. Environmental Controls: Humidity and infection ranges play central roles in bond electricity.This area will element how these aspects contribute to a success cord bonds or workable screw ups.

Common Causes of Wire Bonding Failures

Understanding commonplace failure modes is necessary for strong diagnosis:

- Bond Lifting: Often brought on by inadequate rigidity or temperature settings. Heel Cracking: Typically effects from thermal stress all over operation. Incomplete Bonds: Can stem from incorrect computing device calibration or terrible materials high quality.

These troubles needs to be microelectronics process competently investigated through checking out methodologies like pull checks or shear exams to establish their root factors precisely.

Wire Bond Inspection Techniques

Effective inspection methods model an major component to any twine bonding failure evaluation strategy:

Visual Inspection

Visual inspections serve as the first line of safety opposed to defects. Trained group of workers overview bond high quality utilising magnification resources to spot irregularities reminiscent of incomplete bonds or overseas debris.

Automated Inspection Systems

Automated platforms leverage complex imaging technology to observe anomalies instantly:

- X-ray inspection Acoustic microscopy Optical inspection systems

These applied sciences deliver more actual assessments as compared to guide inspections.

FAQ Section

What are the maximum widespread resources utilized in cord bonding?

Most repeatedly used resources comprise gold, aluminum, copper, and silver wires depending on components like check and application specifications.

How does temperature impression cord bonding?

Temperature performs a essential position; too high can reason damage even though too low may also cause susceptible bonds. It's critical that parameters are optimized based on categorical elements being bonded.

Can I participate in non-detrimental trying out on twine bonds?

Yes! Non-adverse checking out tips including X-ray inspection assist you be certain bond integrity without dangerous the part itself.

What deserve to I do if I suspect a failure in my wire bonds?

If you observed mess ups, conduct thorough inspections the usage of either visual strategies and automated techniques earlier than troubleshooting your technique parameters or methods settings.

How usually must I inspect my wire bonds?

Regular inspections must be section of your high quality management process; after each manufacturing run or batch can support seize matters early on in the past they amplify into higher trouble.

What are a few optimum practices for convalescing bond best?

Ensuring cleanliness on your setting, all the time calibrating system, instructions employees correctly, and following standardized procedures can drastically improve general bond first-class.

Conclusion

Conducting effectual wire bonding failure evaluation requires an awareness of each technical small print exclusive to quite a lot of forms of bondings—such as ball vs wedge—and broader facets like apparatus control and environmental controls. By making use of rigorous inspection tools along thorough competencies of elementary failure modes, mavens can look ahead to attainable worries earlier than they translate into creation losses.

Through this text's insights into the complexities surrounding wire bonding era—from options like ribbon bonding in vigour modules to exploring the consequences of gold vs aluminum—it’s transparent that staying knowledgeable approximately market developments is relevant for achievement during this domain. With non-stop advancements shaping the long run panorama of electronics production, embracing innovation whilst adhering to fine practices will pave the manner closer to attaining more desirable reliability in twine bonded connections throughout all sectors.

This article presents an in depth evaluation at the same time presenting actionable insights into conducting successful wire bonding failure prognosis inside of modern-day electronic manufacturing landscapes—guaranteeing readers are properly-provided with knowledge desirable across a considerable number of fields inside this dynamic enterprise sphere.