Wire bonding is a necessary job inside the electronics manufacturing landscape, taking part in an necessary function in connecting different add-ons within semiconductors, clinical units, and past. The cord bonding manner ensures that electrical connections are made reliably and correctly. In this text, we will be able to delve into the a number of facets of twine bonding applications, exploring its strategies, gear, reliability elements, and lots more and plenty extra.

What is Wire Bonding?

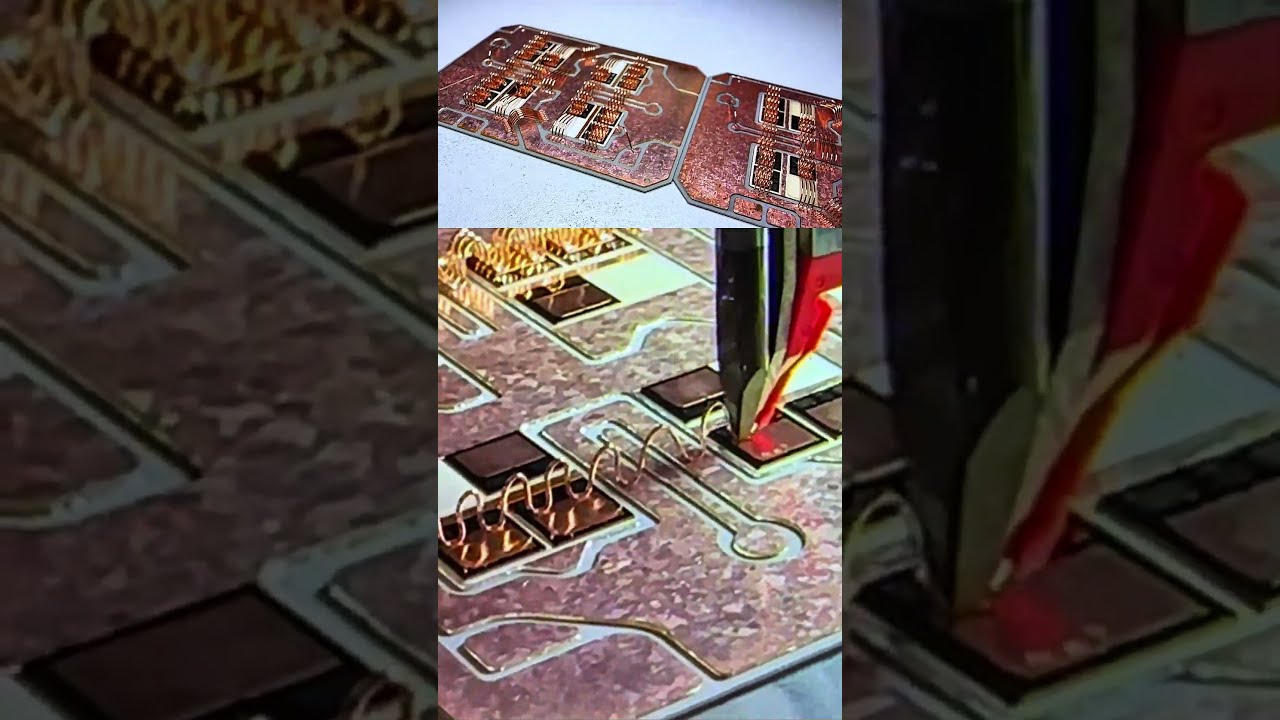

Wire bonding is a way used to create electrical connections among microelectronic aspects. This technique involves the use of first-class wires (basically gold, aluminum, copper, or silver) to connect semiconductor chips to their respective substrates or leads. The procedure will be executed by using a number of programs consisting of ball bonding, wedge bonding, and ribbon bonding.

How Does Wire Bonding Work?

The twine bonding process starts offevolved with the situation of a tiny cord on a delegated bond pad on a semiconductor die. Using heat and rigidity or ultrasonic vigour, the bond is formed with the aid of melting the interface between the twine and the pad. After securing one cease of the twine, this is looped to yet another bond pad wherein it undergoes comparable medical care.

Table 1: Common Types of Bonding Wires | Type | Material | Applications | |---------------|----------------|--------------------------------------| | Gold Wire | Au | High-frequency programs | | Aluminum Wire | Al | Cost-valuable aluminum wire bonding ideas | | Copper Wire | Cu | High recent applications | | Silver Wire | Ag | Specialized digital gadgets |

Wire Bonding Techniques: Overview

There are several processes hired in cord bonding that are chose based on utility specifications:

Ball Bonding

Ball bonding is characterised by forming a small ball at the cease of a cord formerly making a connection. This technique is quite a good suggestion for high-frequency contraptions.

Wedge Bonding

In wedge bonding, the bond tool makes use of a flat surface to create bonds. This method facilitates for higher keep watch over over bond parameters which include temperature and force.

Ribbon Bonding

This really good method utilizes flat ribbons of steel instead of spherical wires. Ribbon bonding presents diminish inductance and improved thermal functionality.

Wire Bonding Equipment: What You Need

To function cord bonding efficiently, specified machines and tools are a must have:

Wire Bonding Machines: These automatic strategies regulate countless parameters all over the bonding strategy. Bonding Tools: Tools like capillary tubes make sure correct managing of ultra-excellent wires. Inspection Equipment: X-ray inspection strategies validate bond integrity without adverse formulation.Wire Bonding Applications: From Semiconductors to Medical Devices

The versatility of twine bonding expertise has ended in its trendy adoption across dissimilar industries:

In Semiconductors

The semiconductor market closely is based on cord bonding for interconnecting incorporated circuits (ICs). Its low fee and high reliability make it acceptable for mass creation.

In Medical Devices

Medical technologies calls for utmost precision; subsequently cord bonding performs an primary role in connecting sensors and microchips utilized in diagnostic kit.

Applications in Electronics Manufacturing

- RF modules Microcontrollers Power electronics

Understanding Wire Bonding Reliability

Reliability in twine bonding refers back to the longevity and robustness of bonds beneath the different stipulations. Factors influencing reliability include:

Material Selection: Choosing excellent components (e.g., gold vs aluminum) can influence functionality. Bond Quality Control: Monitoring strategies by means of inspection equipment ensures defects are minimized. Environmental Controls: Managing humidity and temperature all the way through production continues bond integrity.Common Failure Modes in Wire Bonding

Understanding user-friendly screw ups enables improve approaches:

- Bond Lift: A effect of inadequate adhesion. Heel Crack: Occurs resulting from severe stress on junctions. Oxidation: Degradation brought on by publicity to air.

Cost Implications of Wire Bonding Technologies

The funding in wire bonding applied sciences varies greatly founded on:

- Machine functions (manual vs totally computerized). Material charges (gold vs aluminum). Production amount necessities.

Evaluating Wire Bonding Costs

Cost tests will have to have in mind not best initial investments yet additionally lengthy-time period operational prices including maintenance and drapery wastage.

Quality Control Measures in Wire Bonding

Ensuring pleasant during creation processes contains quite a few solutions:

Visual Inspection: Regular tests guide establish noticeable defects early. Non-destructive Testing: Techniques consisting of X-ray can divulge hidden topics without compromising product integrity. Pull Tests: These tests gauge bond strength readily formerly final meeting tiers.Training Programs for Effective Wire Bonding Execution

To grasp wire bonding suggestions, complete coaching programs are principal:

- Workshops that quilt arms-on trip with methods. Online publications targeting theoretical talents approximately materials and tactics.

Future Trends in Wire Bonding Technology

Emerging traits hint against suggestions that would expand potency:

- Integration with Industry 4.zero standards advertising automation. Development of latest components decreasing quotes whereas sustaining functionality ranges.

FAQs approximately Wire Bonding

1. What varieties of bonds are characteristically utilized in wire bonding?

Common models consist of gold ball bonds, aluminum wedge bonds, and ribbon bonds appropriate for definite programs like pressure modules or RF circuits.

2. How do I make certain solid great regulate for the period of wire bonding?

Adopt regular inspection practices simply by visible exams and non-unfavourable trying out programs like X-ray inspection to observe bond integrity invariably.

three. What are some traditional mess ups encountered all through the wire bonding procedure?

Common failures encompass bond raise-off resulting from insufficient adhesion, heel cracks from extra tension at junctions, and oxidation from environmental publicity.

four. Is there a primary expense big difference between gold vs aluminum twine?

Yes! Gold wires normally payment more than aluminum yet offer sophisticated conductivity which can also justify their use depending on application demands.

five. How does environmental handle have an affect on wire bond reliability?

Maintaining top of the line humidity ranges prevents oxidation while managed temperatures decrease thermal rigidity all over processing levels making sure physically powerful bonds.

6. Are there training publications achievable for mastering approximately sophisticated cord bonding innovations?

Yes! Many institutions offer specialised exercise systems ranging from straight forward tutorials to developed workshops focusing on modern applied sciences involving wire bonding tactics.

Conclusion

Wire bonding stays an invaluable era throughout diverse industries starting from semiconductors to clinical units by way of its versatility and validated reliability over the years. Understanding its recommendations—like ball versus wedge as opposed to ribbon—and enforcing powerful nice regulate measures will ensure that a success program result whilst minimizing quotes related to construction inefficiencies or disasters down the line!

By staying informed about rising developments inside of this area—comparable to Industry 4 .0 improvements—brands can extra refine their operations foremost toward even stronger efficiencies shifting forward!