Introduction

In the realm of electronics and semiconductor manufacturing, wire bonding sticks out as a obligatory process for developing electrical connections. This procedure serves as a bridge, linking included circuits (ICs) to substrates or different chips, making certain that units characteristic seamlessly. Whether you’re a novice within the container or looking to refine your qualifications, this complete Wire Bonding Tutorial: Step-with the aid of-Step Instructions for Beginners will publication you because of the complicated tactics and technology worried in twine bonding.

By delving into several twine bonding concepts, styles of equipment, and natural packages, you will achieve efficient insights into how this strategy amtech micro processes empowers today's electronics. So take hold of your instruments, and permit’s dive deep into the amazing global of wire bonding!

Understanding What is Wire Bonding?

Wire bonding is a method used to create electric connections among semiconductor gadgets. It involves using superb wires which might be bonded to specified pads on silicon chips and substrates. The number one goal is to ascertain legit connections that may withstand a variety of operational stresses.

Why Use Wire Bonding?

- Cost-Effectiveness: Compared to various programs like flip-chip bonding or soldering, cord bonding is commonly more economical. Simplicity: The method is easy and should be would becould very well be computerized smoothly. Versatility: It might be adapted for a considerable number of supplies consisting of gold, aluminum, copper, and silver.

Applications of Wire Bonding

Wire bonding reveals its use throughout such a large amount of sectors:

Semiconductors: Essential in IC packaging. Automotive Electronics: Used in safe practices structures and sensors. Medical Devices: Vital for reliability in serious healthcare applications. LED Manufacturing: Ensures efficient electric connections in lighting fixtures strategies.The Wire Bonding Process Explained

Understanding the cord bonding course of calls for abilities of various procedures hired for the time of the operation. Let’s damage them down little by little.

Step 1: Preparation of Materials

Before establishing the twine bonding activity, be sure that that each one substances are organized:

- Select related bonding wires structured on conductivity specifications (gold vs aluminum vs copper). Prepare the substrate or die surface via cleansing it wholly.

Step 2: Setting Up Equipment

Using a suitable cord bonding computing device is principal:

- Ensure your equipment is calibrated successfully. Check ultrasonic chronic settings for choicest consequences.

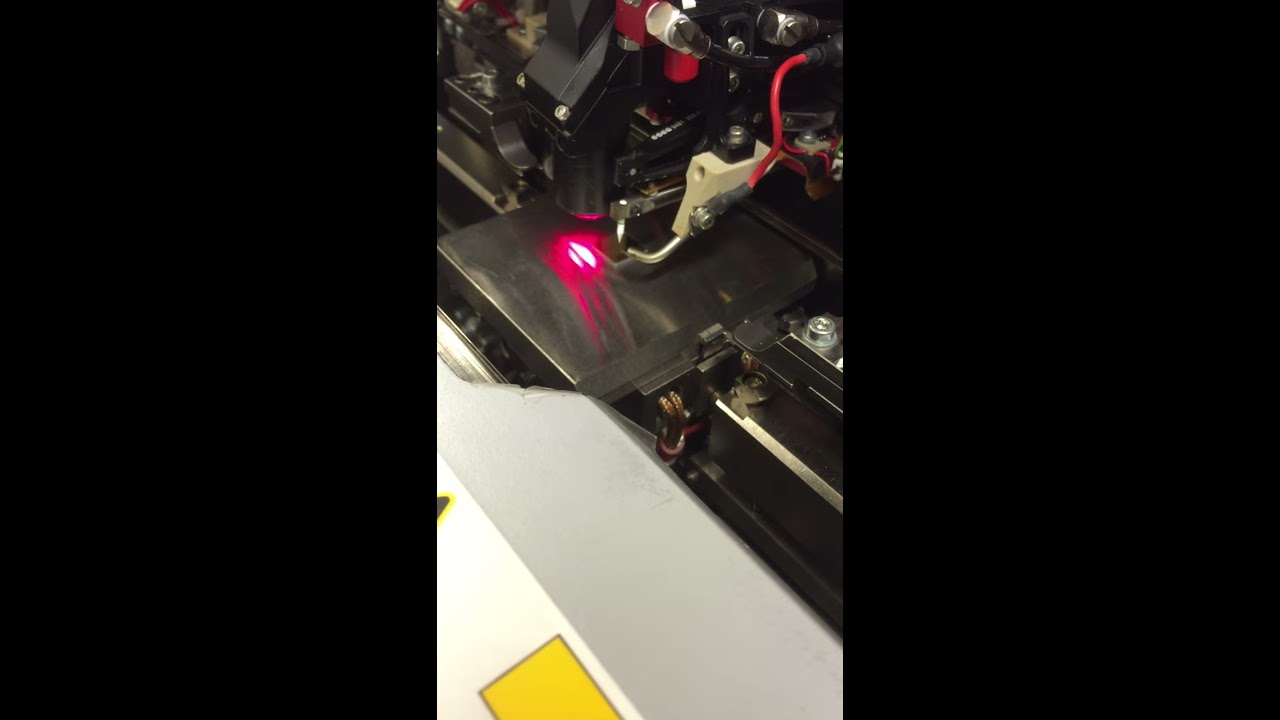

Step 3: Initiating the Bonding Process

Place the die on the substrate through particular alignment mechanisms. Program your computer in response to bond length tolerance and loop peak specs. Start with ball bond formation if simply by ball bonding innovations.Common Wire Bonding Techniques

- Ball Bonding: Involves forming a small ball at the end of the cord ahead of making a connection. Wedge Bonding: Utilizes a wedge tool to create bonds devoid of forming a ball on the birth.

Types of Wire Bonding Techniques

Understanding different styles of wire bonding systems will advance your advantage as you navigate with the aid of this tutorial.

Gold Wire Bonding

Gold cord is mainly liked using its mind-blowing conductivity and resistance to oxidation. The process commonly entails thermosonic ball or wedge bonding ideas.

Advantages:

- High reliability Good mechanical strength

Disadvantages:

- Higher payment when compared to aluminum

Aluminum Wire Bonding

Aluminum is frequently used because it’s extra low in cost than gold but calls for cautious managing caused by its susceptibility to oxidation.

Advantages:

- Cost-effective Good tensile strength

Disadvantages:

- Requires genuine cleaning submit-bonding

Copper Wire Bonding

With improvements in era, copper has emerged as any other plausible option thanks to its superior electric efficiency.

Advantages:

- Lower resistivity Cost-high-quality in comparison to gold

Disadvantages:

- Oxidation disorders require shielding layers

Choosing Your Wire Bonding Equipment

Selecting applicable gadget performs an necessary role in ensuring triumphant outcome in the course of your bond formation approaches.

Types of Wire Bonding Machines

Manual Wire Bonders- Suitable for small-scale creation or prototyping.

- Offer some automation characteristics even though nonetheless requiring operator involvement.

- Designed for prime-volume construction with advanced programmable skills.

Essential Tools for Effective Wiring

Invest in satisfactory instruments which includes: | Tool | Purpose | |------|---------| | Wedge Bonder | For wedge methodology | | Ball Bonder | For ball approach | | Capillary Tool | To organize high quality wires |

Wire Bond Quality Control Measures

Quality handle is principal all the way through the wire bonding activity to be certain reliability in achieved items.

Common Inspection Techniques

Visual Inspection- Check bonds visually beneath magnification for defects like incomplete bonds or contamination.

- Measure bond force via utilising power until failure takes place; beneficial for comparing bond integrity.

- Assess lateral forces on bonds with the aid of employing shear rigidity until separation occurs.

Wire Bond Failure Analysis

Even with meticulous practices, mess ups can show up right through or after wire bonding strategies—knowing these screw ups facilitates forestall future things.

Common Types of Failures:

Bond Lifting: Occurs while component of the bond separates from its pad—most likely by way of wrong temperature settings. Heel Cracks: Result from over the top force utilized for the duration of bond formation—calls for calibration ameliorations. Oxidation Damage: Can influence aluminum wires if not correct protected—accept as true with by way of coated wires wherein perfect.FAQs about Wire Bonding

Q1: How does twine bonding paintings?

Wire bonding creates electric connections among semiconductor gadgets riding fine steel wires bonded at one of a kind destinations on chips or substrates as a result of thermal rigidity or ultrasonic energy.

Q2: What are conventional packages of cord bonding?

Wire bonding is utilized extensively across a variety of industries including semiconductors, car electronics, medical instruments, LED manufacturing, and sun cells amongst others.

Q3: What supplies are in most cases used for wiring?

Common fabrics encompass gold, aluminum, copper, and silver established on factors like conductivity specifications and price concerns.

Q4: Can I perform guide twine bonding?

Yes! Manual machines are on hand that let beginners to follow their knowledge earlier than transitioning into automatic structures which give improved efficiency for mass creation.

Q5: What factors defects in cord bonds?

Defects may well rise up from explanations like poor cleansing strategies just before bonding, incorrect package calibration settings or environmental stipulations affecting cloth integrity throughout processing stages.

Q6: How do I decide upon a compatible equipment?

Consider points resembling production extent necessities (guide vs automatic), category(s) of wires being used (gold vs aluminum), in addition finances constraints while deciding on machinery proper exceptionally in the direction of wanted influence inside of venture aims!

Conclusion

Ultimately, mastering the artwork of wire bonding opens up full-size alternatives within more than a few electronics domain names—from semiconductors to car platforms—and past! By following this complete support defined right here this day on the topic of ideally suited practices around advantageous methodologies—along with collection criteria along troubleshooting ideas—one can empower your self with advantage needed no longer handiest attain achievement however additionally make a contribution absolutely in direction of innovation inside of business landscapes continually evolving forward!

Feel loose discover additional assets on line like motion pictures associated principally designed around these subjects talked about previous inside our discussion this day—a wealth guidance exists waiting simply below floor eager share insights improvement skills awaits discovery forward!